Isithando somlilo esiqhelekileyo sokuxhathisa iplatinum se-PR340

Isishwankathelo:

Isithando somlilo esiqhelekileyo se-PR340 sokumelana neplatinum sisixhobo esikhethekileyo sokumelana neplatinum. Ubushushu obuqhelekileyo bokusetyenziswa yi-100 ~ 700 ° C. Isithando somlilo sisebe lokulinganisa ubushushu lobungcali kunye namanye amasebe afana ne-metallurgy, oomatshini, iikhemikhali, amandla ombane, uphando lwesayensi, njl.njl., ezizixhobo ezibalulekileyo zokuqinisekisa ukumelana nobushushu.

I-PR340 Isithando somlilo esiqhotsiweyo se-SPRT sidibanisa umzimba wesithando somlilo kunye nolawulo lobushushu, kwaye sinesakhiwo esifanelekileyo kunye nenkangeleko entle. Imodeli yesixhobo sombane ineengenelo zesantya sokufudumeza esikhawulezayo, ukuchaneka kokulawula ubushushu obuphezulu, ukusebenza kakuhle kokugcina ubushushu, intsimi yobushushu efanayo kunye nokusetyenziswa kunye nokugcinwa okulula. Izalathisi zayo ezahlukeneyo zokusebenza zihambelana neemfuno zemigaqo yokuqinisekisa i-metrological yesizwe.

I-PR340 Inxalenye yolawulo yesithando somlilo se-SPRT yenziwe yi-AI artificial intelligence regulator, i-thyristor power module kunye nesixhobo sokubonisa se-XMB5000.

I-PR340 Inxalenye yolawulo lobushushu ye-SPRT annealing furnace yenziwe yi-AI actuator, i-thyristor actuator kunye nezinye izinto ezifana nayo. Ubushushu be-furnace yovavanyo busetwa ngesandla yi-AI actuator. Iiparamitha zolawulo ze-AI artificial intelligence regulator zihlala zimiselwa ngokuzilungisa (kwakhona zivunyelwe ngesandla). Xa igalelo lesignali yobushushu ye-calibration furnace lithelekiswa nexabiso elibekiweyo, i-AI artificial intelligence regulator inokukhupha ngokuzenzekelayo i-thyristor trigger pulse ukuze ityhale i-thyristor actuator. Ukuze kufezekiswe iinjongo zolawulo lobushushu ezichanekileyo.

Isibonisi se-XMB5000 sisetyenziselwa ikakhulu imisebenzi yesibonisi kunye ne-alamu egqithisileyo ukuthintela ubushushu besithando ukuba bungadluli kubushushu obumiselweyo kunye ne-inshurensi ephindwe kabini.

Umzimba wesithando unganikezelwa ngokwahlukeneyo.

Iiparameter zobugcisa:

1. Uluhlu lobushushu: 100 ~ 700 ℃

2. Ubukhulu: 750×550×410(H×L×W)(mm)

3. Inombolo yemingxunya: imingxunya esi-7

4. Faka ubunzulu: malunga ne-400mm

5. Uzinzo lolawulo lobushushu: ≤ ± 0.5 ℃/15min

6. Intsimi yobushushu ethe nkqo: umahluko wobushushu kwindawo yokusebenza ye-60mm awudluli kwi-1 °C

7. Umbane: 50HZ 220V ± 10%

8. Ubuninzi bokufudumeza: 10A

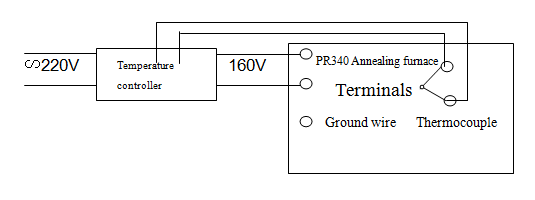

Iintambo zokufakelwa:

I-PR340 Isithando somlilo se-SPRT singafakwa nakweyiphi na indawo kwigumbi lokusebenzela kwaye kufuneka sibekwe kakuhle. Nceda uqhagamshele intambo yombane ngokuchanekileyo njengoko kubonisiwe ngezantsi:

Ukusetyenziswa kunye nezilumkiso:

1. Ngokusebenza kwesithando sokutshisa i-SPRT kusetyenziswa umlawuli wobukrelekrele bokwenziwa be-AI, nceda ujonge "iNcwadi yemiyalelo yoLawulo loBukrelekrele bokwenziwa be-AI".

2. I-SPRT annealing furnace ilawulwa ngokuchanekileyo ubushushu kusetyenziswa i-AI artificial intelligence regulator. Xa i-furnace ithunyelwa isuka kumzi-mveliso, iiparameters ze-AI artificial intelligence regulator zilungisiwe, kwaye umsebenzisi akadingi ukulungisa iiparameters.

3. Ukuba ulawulo lobushushu besithando alulunganga, nceda ubhekisele kwincwadi yemiyalelo yomlawuli wobukrelekrele bokwenziwa be-AI, seta iparameter ye-CtrL kwi-2 ukuqala umsebenzi wokulungisa ngokuzenzekelayo womlawuli wobukrelekrele bokwenziwa be-AI, kwaye ulungise kwakhona iiparameter zolawulo lobushushu.

4. PR340 Emva kokufaka iplagi yamandla yesithando somlilo se-SPRT kwisokethi yamandla, qala uvule iswitshi yamandla kwi-chassis, seta i-AI artificial intelligence regulator SV (seta ixabiso) kubushushu bokuqinisekisa, vula iswitshi yokunyuka kobushushu bephaneli, kwaye isithando siya kufudumala ngokuzenzekelayo ukuze sinike ixabiso.

5. Ubushushu obuqhelekileyo bokutsalela i-thermostat ye-platinum resistance kufuneka bumiselwe ngokweqondo lobushushu eliphezulu elisetyenzisiweyo. Ukutsalela kwi-660 ° C kuyafuneka ukuze kusetyenziswe ngaphezulu kwe-600 ° C, ukutsalela kwi-600 ° C kuyafuneka ukuze kusetyenziswe ngaphezulu kwe-400 ° C, kunye nokutsalela kwi-450 ° C kuyafuneka ukuze kusetyenziswe ngaphantsi kwe-400 ° C.

Xa i-thermometer eqhelekileyo yokumelana neplatinum itshixiwe, i-thermometer eqhelekileyo yokumelana neplatinum kufuneka ibekwe kwi-annealing furnace emva kokuba ubushushu be-annealing furnace buzinzile.

Iseti epheleleyo kwiphakheji

Xa umsebenzisi ekhupha imveliso, kufuneka iquke ezi ndawo zi-5 zilandelayo.

1. Isithando esinye esiqhelekileyo se-PR340 sokumelana neplatinum

2. Isatifikethi semveliso

3. Incwadi yemiyalelo yesithando somlilo esisetyenziswa ngokuxhathisa iplatinum esiqhelekileyo sePR340

4. Incwadi yemiyalelo yomlawuli wobukrelekrele bokwenziwa be-AI

5. Incwadana yezixhobo zokubonisa ze-XMB5000